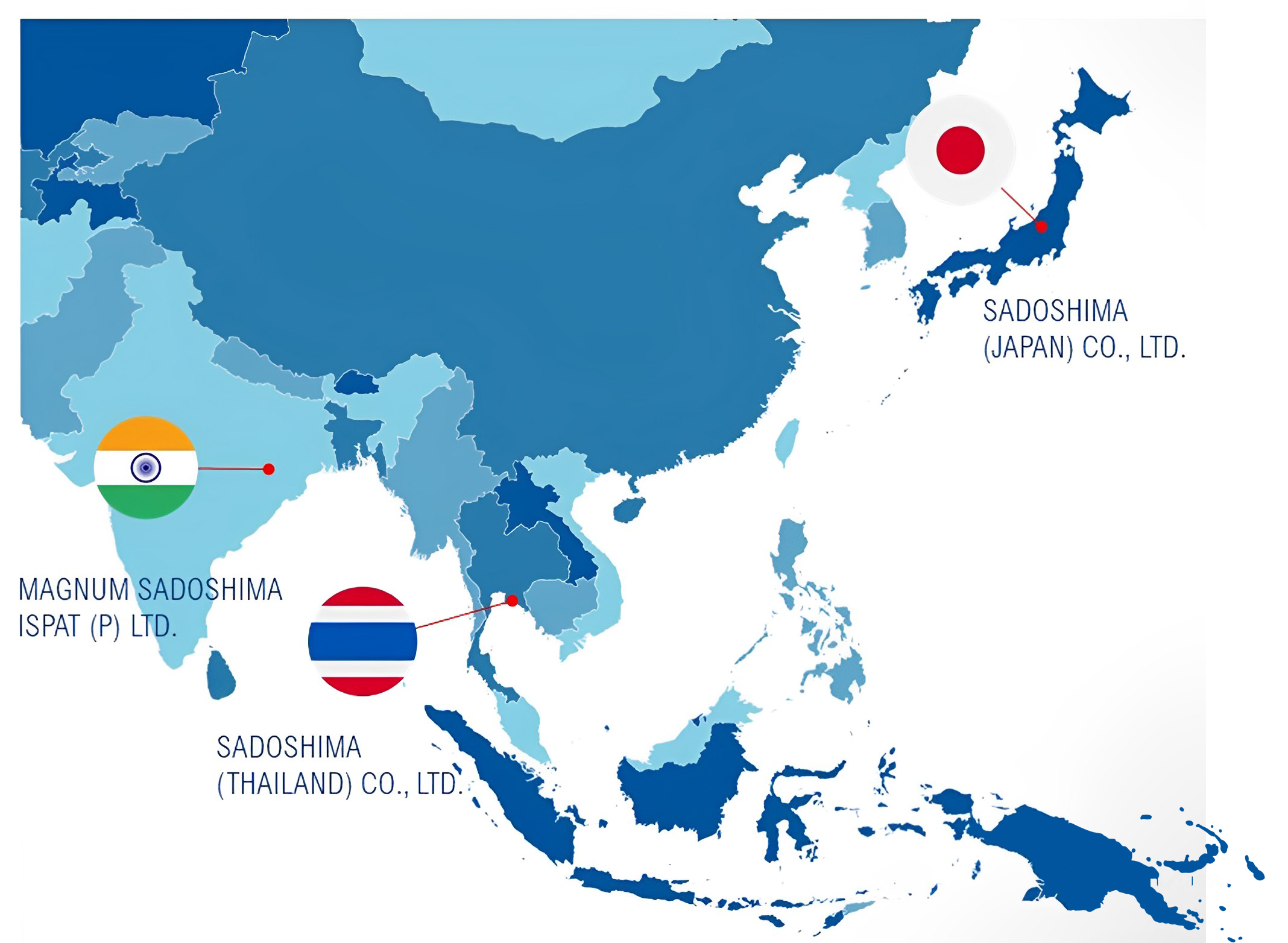

SADOSHIMA (THAILAND) CO., LTD.

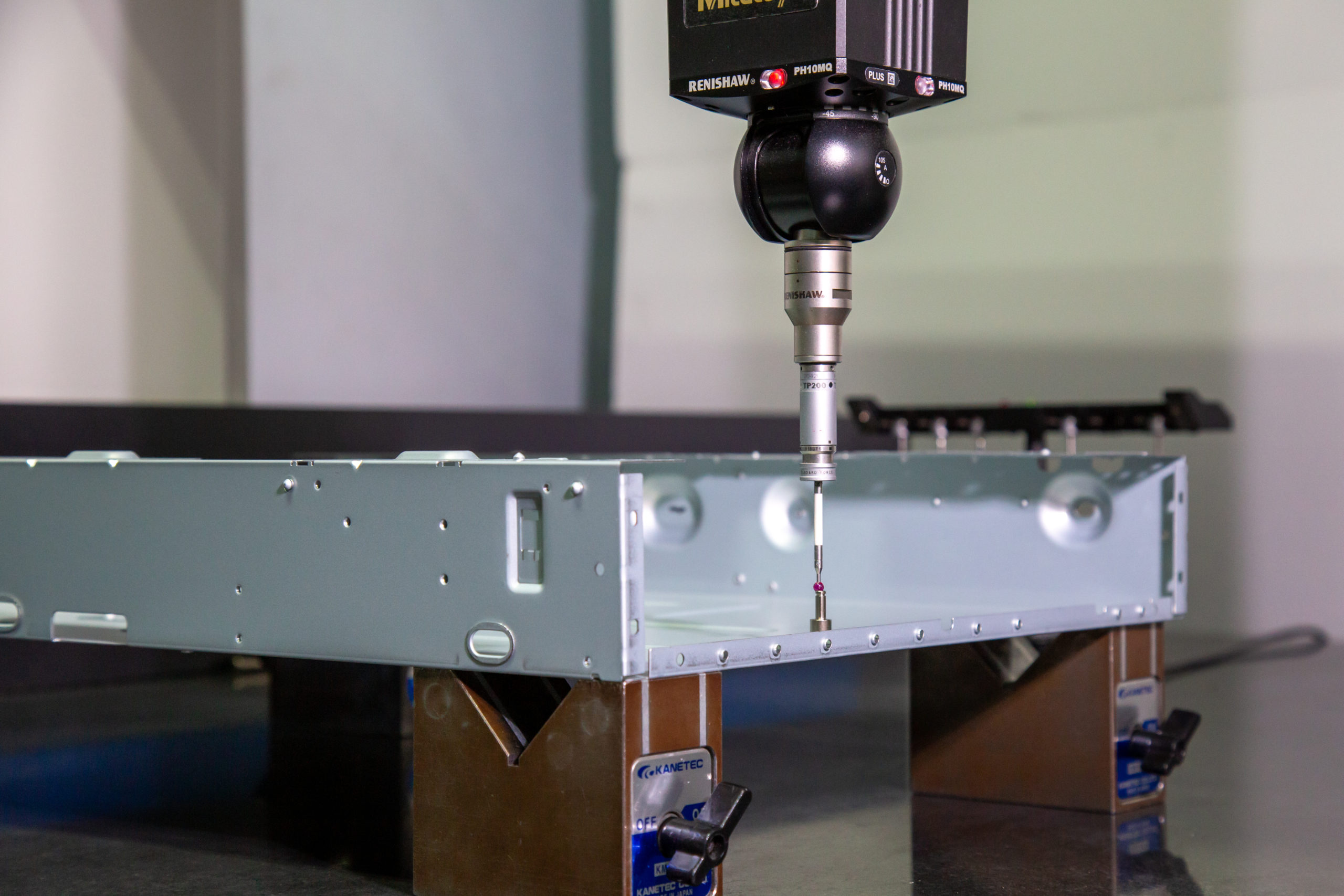

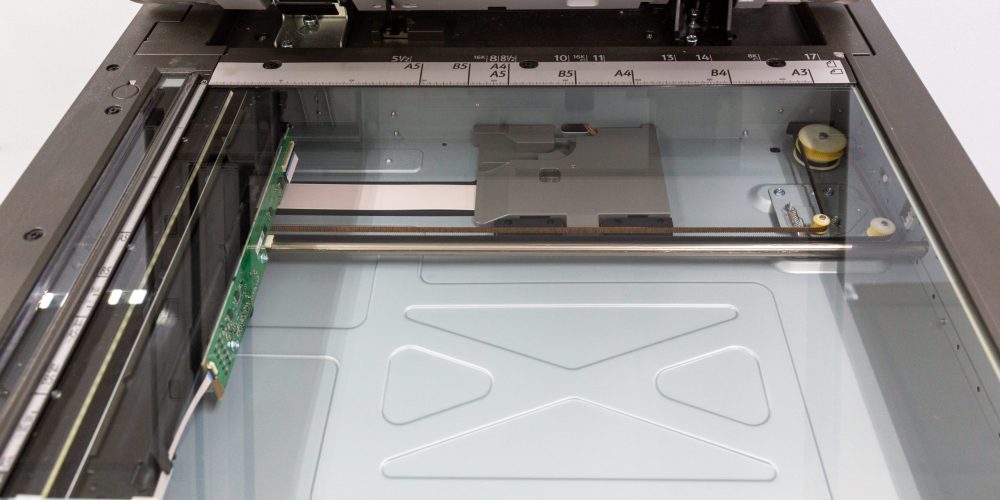

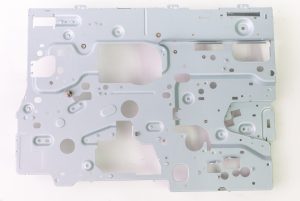

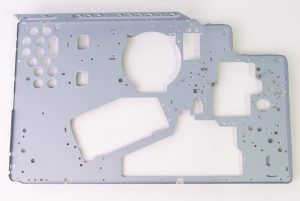

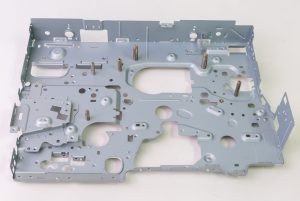

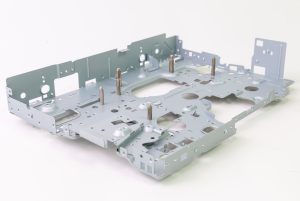

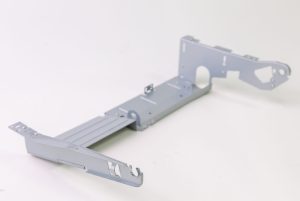

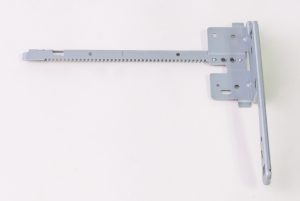

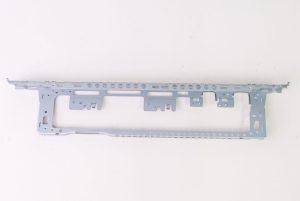

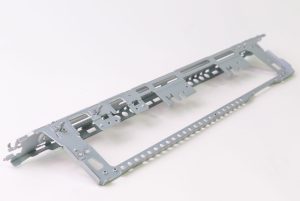

Metal Stamping and Sub-assembling for Precision Machinery

Sadoshima (Thailand) Co., Ltd. provides high-precision press parts and sub-assembling of OA complexes and other equipment for the electronics industry

| Company Name | Sadoshima (Thailand) Co., Ltd. | ||

| CEO & President | Mr. Nobuyuki Yamanaka | ||

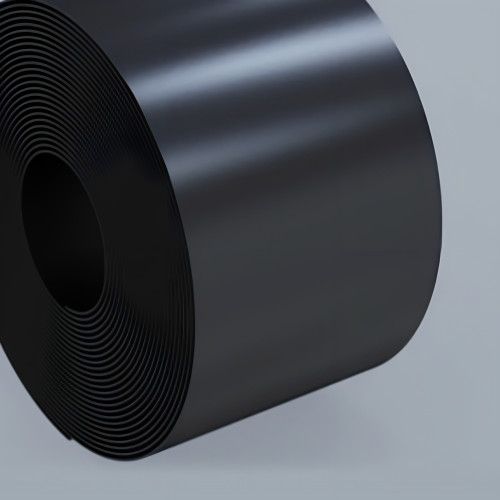

| Business Description | Metal Pressing, Semi-Assembling and other related processing Domestic and International trading of Precoated materials, Steel coated sheet and Non-Ferrous products. | ||

| Address | Amata City Rayong Industrial Estate 7/437 Moo 6, Tambol Mabyangporn, Pluak Daeng, Rayong 21140 Thailand | ||

| TEL 038-027-508, 510, 511 FAX 038-027-509 | |||

| For Thai | Suriwassa – suriwassa.c@sadoshima.co.th 038-027-508, 510, 511 | ||

| For Japanese | Kobayashi – kobayashi.tetsuo@sadoshima.co.th 061-3843499 | ||

| Website | http://www.sadoshima.co.th | ||

| Establishment Date | December, 2012 | ||

| Capital | THB195,000,000 | ||

| Parent Company | Sadoshima Corporation 1-16-19, Shimanouchi, Chuo-ku, Osaka 542-0082 Japan | ||

| Employee | 240 persons | ||

| Bank | Bank of Ayudya | ||

| BOI | January, 2014 | ||

| Certificate | ISO9001:2015, ISO14001:2015 (Acquired in Dec, 2016) IATF16949:2016 (Scheduled to acquire) |